Essential Oils Process

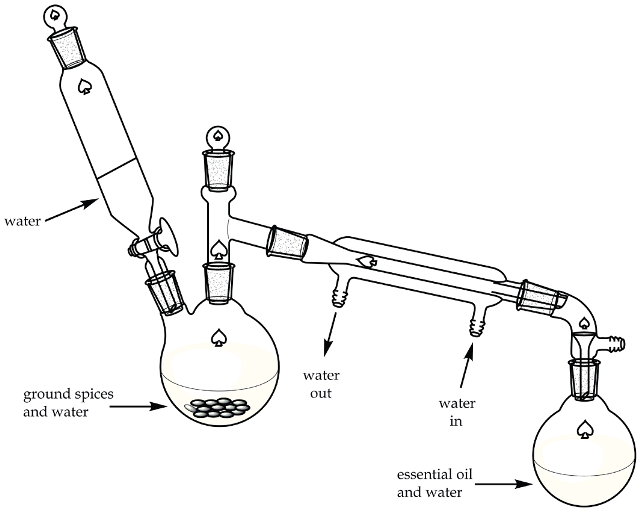

Steam Distillation

Steam distillation is the most common way to extract aromatic compounds (essential oil) from a plant. During the steam distillation process, steam passes through the plant material. The combination of heated steam and gentle pressure causes the essential oil to be released from microscopic protective sacs. As the vapor mixture flows through a condenser and cools, it yields a layer of oil and a layer of water. The essential oil rises to the top and is separated from the hydrosol (floral water) and collected.

Some have asked about the difference between first distillations in comparison to complete distillations. The temperature for steam distilling is usually between 140–212 degrees Fahrenheit. Since different plants require different pressures, times, and temperatures, using this particular distillation method makes it possible to adjust the temperature based on the plant type, making it a very effective and precise way to obtain the purest compounds.

Expression

Unlike steam distillation, expression, sometimes referred to as “cold pressed,” does not involve heat. In this process, oil is extracted from the product under mechanical pressure. We uses expression to extract all of its citrus oils, such as Wild Orange, Lemon, Lime, Bergamot, and Grapefruit, from the rind.

Proper distillation requires a consideration for the uniqueness of pressure, temperature, time, and harvesting practices, each of which may be as diverse as the plants themselves. A poor distillation process can alter or destroy the necessary aromatic compounds that comprise the essential oil, leaving a substance far different from the intended goal and something that would not be used to support health and wellness. For this reason, the best distillation artisans dedicate their efforts and work to only a few select plants. This focused effort develops proper knowledge and experience, helping ensure congruency between the oil chemistry of the plant and its distilled form.